Our 55 gallon drum for the dyno muffler has been modified with a 4 inch inlet at the bottom, provisions for feet, and necessary in this drums case the top has been cut off. Now the drum is ready for some sound deadening exhaust packing. Because the drum is such a large diameter compared to what a normal muffler would be we have a lot of room for material which should ultimately help keep the noise down. I needed to get this project completed quite so I could continue product testing our RZR Turbo Velocity Intake system, and also had a RZR 900 S coming in for a new intake design and pwrtuneECU tuning.

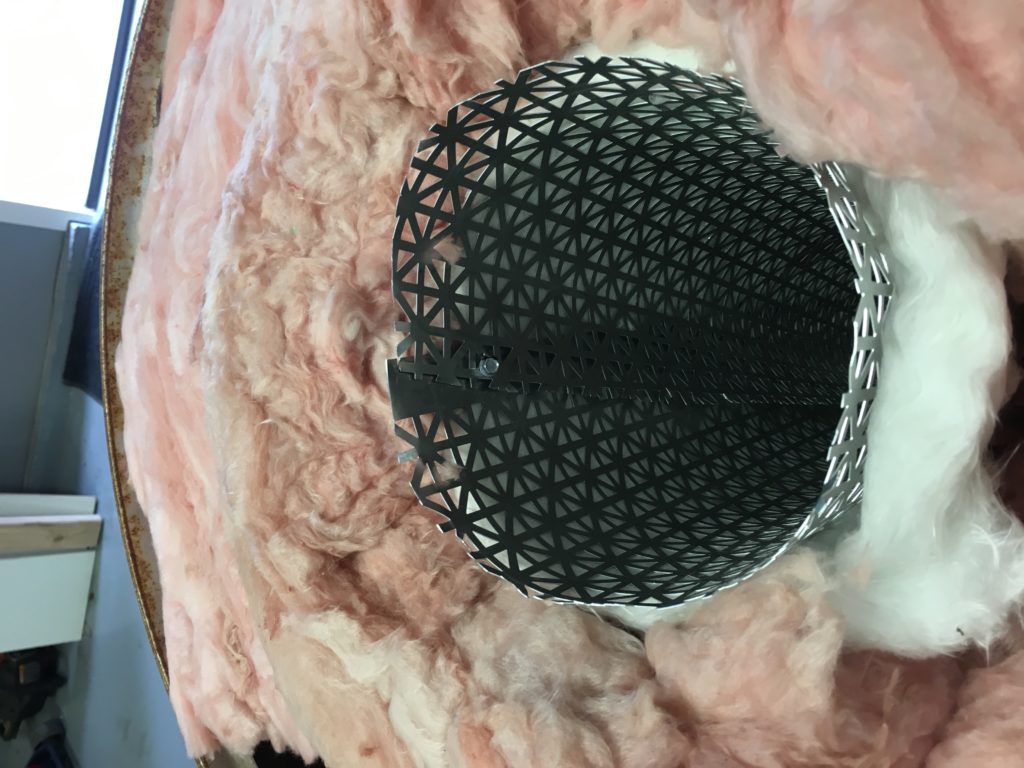

Not really sure how well this entire project will work out, initially I did not want to use a large amount of expensive exhaust packing to fill the drum. I have several large rolls of BGF techmat high quality exhaust packing at the shop, but filling the drum would require two entire rolls and if the drum muffler did not work out the packing would be useless. So instead I decided to fill with pink home insulation from home depot on the outermost edges, and I would use one layer of real exhaust packing on the inside that would contact the perforated core. I started with a small square of insulation at the bottom (see pic) and about half of a roll of the unfaced pink insulation placed that I placed into the drum filling the bottom half of the space. I carefully put an inner layer of the white exhaust packing inside that so the half the drum was packed. Then I inserted the perforated core before I filled up the rest of the drums. It didn’t look like I could fill up the drum and then put the core in, nor did it look like I could put in the core and then fill the drum, so I did half and half. The inner perforated core that I used I also got from home depot, it was a 40”x40” sheet of aluminum about 22ga. covered in triangular holes. Normally for a muffler the holes in the core would have been too large allowing most of the exhaust packing to easily escape. But since the muffler core it would start at a bottom 4” diameter and taper up to an 8” I didn’t see the packing easily escaping running at max 1000cc Polaris RZR UTV motors. We on our dyno we run.

I finished the packing with the pink insulation on the inside and one layer of exhaust packing on the inside, you can see from the two pics the packing with core sticking out. Next I cut a hole in the drum lid and used an HVAC 8” starter take off for the outlet. Placing the lid on the drum the muffler core came into the 8” take off about 2” just enough to secure of with some high temp tape. The 55 gallon drum has now been converted into a dyno muffler with a 4” inlet at the bottom and 8” outlet on the top. The last thing I wanted to do was install a fan at the outlet to help keep the back pressure down and then will be ready to test.

For more updates visit us at www.powersportsefi.com